Making solar panels is awful for the environment. This new design may be the cure.

Solar power to produce more CO2 than aviation by 2050, report finds.

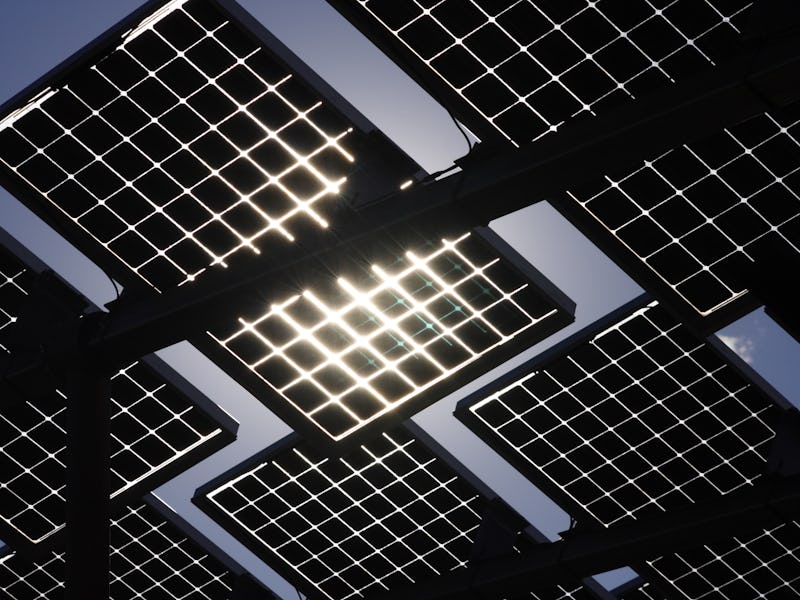

When it comes to combatting the planet's rising temperature and carbon emissions levels, renewable energy options like solar panels are a clear path of action. But despite the obvious environmental advantages of such an approach, authors of a new energy analysis write that current solar power technology has a larger carbon footprint than you might think. While it hovers around two percent today, as solar energy continues to scale in the coming decades, the authors write that emissions from solar technology could eclipse that of international aviation at about five percent the world's total energy budget.

In a study published Monday in Joule, researchers analyze these trends and demonstrate how a new approach to solar cell design could lower solar emissions twenty-fold and bring the technology close to its lowest emissions yet.

While the impact of solar energy on carbon emissions may seem counterintuitive, the authors write that its lurking carbon impact lies in both manufacturing energy expenses, differing efficiency standards across global sectors and the technology's anticipated scaling in the coming years.

"First, the carbon footprint of PV [photovolatics] depends on the total CO2 emitted during production, which is determined by the industrial requirements of the specific PV technology used and the maturity and efficiency of the manufacturing industry," write the authors. "For example, the footprint of a Si-PV [silicon photovolatic] module produced in China is twice as high in comparison to a production in the EU or the US due to a different degree of industrialization and environmental restrictions."

The authors considered three different future scenarios for the silicon-based solar cells we use today, ranging from optimistic to realistic emission levels, and found that in all scenarios the total level of carbon emissions created through these technologies was more than the international aviation industry as a whole.

"In all scenarios, within the next ten years, the annual CO2 emissions from the global PV industry will exceed the current emissions of international aviation," write the authors. "[O]ur findings illustrate that the (non-)sustainability of so called ‘‘sustainable systems’’ like RE [renewable energy] technologies needs to always be assessed and moved to the focus of future research and development."

To curb this anticipated barrage of emissions, the authors write that turning attention to a lower-cost, more efficient form a solar cell will be important. Enter: the reverse manufactured perovskite solar cell. While this kind of solar cell, which is based on inorganic perovskite instead of silicon, has long been heralded as the next generation to solar cells thanks to their improved efficiency and lower cost, models have yet to make it from the lab into production because of design hurdles including concerns about lead leaching into water and the cells' shorter life capacity.

To help perovskite cells prepare for their big debut, researchers of this study describe a new way to design these cells to improve their lifespan that sounds similar to how you might imagine a gusher is created.

To design this new solar cell, researchers sealed off glass chambers and then injected perovskite in the center. This approach helped seal the chemical material off and prevent future degrading.

In their model, they made used glass sealing methods borrowed from windshield manufacturers to make an airtight seal for each section of the solar cell that will prevent oxygen from seeping in and degrading the perovskite. Once these airtight, glass cells were created the researches injected the perovskite material into the cell, removed any remaining gas in the system and resealed the cell.

While these models were still not perfect, the authors write that they still demonstrated significantly lowered carbon emissions compared to traditional solar cells and could demonstrate the first steps towards a new stable, efficient form of solar energy.

"We are convinced that our results will promote research away from employing complicated, in stable organic charge conductors and metallic contacts toward inert, inorganic materials such as graphite or metal oxides," write the authors. "In combination with our introduced long-term stable glass encapsulation concept, this will guide the direction for future perovskite development, thus paving the way toward industrial realization of long-term stable PV modules with lowest carbon footprint."

Summary: Although it still contributes to less than 2% of the worldwide electricity generation, photovoltaics (PVs) is on the way to becoming a key energy technology for a global future renewable energy infrastructure. We present projections of worldwide CO2 emissions of the future PV industry, finding that these emissions will likely surpass those caused by the global shipping or aviation sector. As an alternative, we propose a fully printed PV reverse manufacturing concept that minimizes the carbon footprint to the ultimate lower limit of the glass substrate fabrication. This so called ‘‘in situ’’ approach is based on a perovskite absorber that is highly durable and encapsulated with glass solder between float glass substrates, reducing the CO2-footprint of conventional PV modules by 1/20th. Yielding a certified stabilized efficiency of 9.3%, this record efficiency for glass-solder-encapsulated perovskite PV paves the way for future solar cells with the lowest carbon footprints.